Region of Peel: Large-Scale Metallic Watermain Condition Assessment

The Region of Peel assessed over 50 km (31 mi) of metallic watermains using non-invasive vibroacoustic inspection to strengthen its risk-based renewal framework. By integrating Dynamic Response Imaging™ data into its Decision Support System, the Region improved deterioration modeling, prioritized 22 km of high-risk mains for renewal, and optimized long-term capital planning.

The Challenge

The Region of Peel (the Region) operates one of Canada’s largest water distribution and transmission systems, delivering safe drinking water to approximately 1.5 million residents and more than 175,000 businesses across the cities of Mississauga, Brampton, and the Town of Caledon. The network includes more than 4,700 km (2,920 mi) of watermain assets constructed from a variety of pipe materials and sizes.

While much of the distribution system has been modernized with Polyvinyl Chloride (PVC), approximately 420 km (260 mi) of older metallic iron mains remain in service, primarily constructed of Cast Iron (CI) and Ductile Iron (DI). These pipelines are more susceptible to failure due to their age and exposure to aggressive soil conditions, which contribute to increased watermain breaks. As a result, optimizing capital expenditures by prioritizing iron watermain assets most likely to fail is essential to maintaining a proactive renewal strategy rather than a reactive “fix-it-when-it-breaks” approach.

Traditional approaches to watermain renewal—based on pipe age or break history—are commonly used across the industry to prioritize work at a network level. However, these methods often fail to capture true pipe condition and can lead to premature replacement. To address these limitations, the Region has advanced its renewal strategy by incorporating direct condition assessment and predictive analysis grounded in engineering principles. This approach reduces uncertainty around when and where to invest, while generating a robust dataset that supports future modeling and improves the ability to identify critical mains approaching failure.

Previous replacement programs confirmed the limitations of age-based decision-making, with several iron mains replaced earlier than necessary. In response, the Region developed a proactive, risk-based decision-making framework that integrates deterministic, statistical, and probabilistic methods supported by machine learning and field-collected data. At the core of this framework is the Region’s Decision Support System (DSS), which consolidates asset information and risk modeling to prioritize renewal activities more effectively.

To strengthen and calibrate this system, Peel required actionable condition data that could inform deterioration curves, improve confidence in remaining service life predictions, and guide long-term capital planning.

The Approach

To generate this level of actionable insight, the Region engaged KenWave Solutions (KenWave) to deploy its patented Dynamic Response Imaging™ (DRI™) solution. DRI™ is a non-invasive, external vibroacoustic method that estimates pipe wall condition using a moving average over short pipe segments—typically 2 to 3 metres (5 to 10 feet)—providing insights into wall thickness, identifying localized deterioration, and detecting leaks simultaneously. By delivering direct structural data while maintaining operational ease and avoiding service interruption, DRI™ provided the Region with defensible condition insights to support its renewal prioritization process needed to enhance their renewal prioritization process as well as the ability to calibrate and enhance its predictive models within the DSS framework.

Between 2024 and 2025, more than 50 km (31 mi) of metallic iron mains were inspected using this approach. The resulting datasets were integrated into the Region’s risk models in collaboration with GHD, enabling recalibration of initial deterioration curves and improving confidence in remaining service life predictions.

How Did DRI Perform?

The inspection program delivered a comprehensive dataset that directly informed Peel’s renewal strategy. Key findings included:

- Over 50 km (31 mi) of metallic mains were assessed through two field mobilizations conducted over approximately one to one-and-a-half months, surpassing the Region’s original target.

- Detailed wall thickness profiles, averaged over approximately two-metre pipe sections, revealed localized areas of pitting and pipe wall loss. These results support the use of complementary indirect assessment methods to evaluate soil conditions along the inspected watermains, further enhancing deterioration curves and improving predictions of remaining service life.

- Leak detection confirmed active issues on iron mains, including segments in corrosive soils.

- Optimized high-risk mains identified: Approximately 22 km (14 mi) were prioritized for near-term renewal.

- Calibration of initial deterioration curve: The initial deterioration curve was developed using available traditional acoustic data with a mean absolute error of approximately 0.05 mm/year. Using DRI inspection data, the deterioration curve was calibrated and enhanced with a mean absolute error of approximately 0.01 mm/year, demonstrating a significant improvement in alignment between predicted and observed condition trends.

- Moderate-risk mains deferred: lower-risk assets scheduled for continued monitoring, optimizing the timing of future investments.

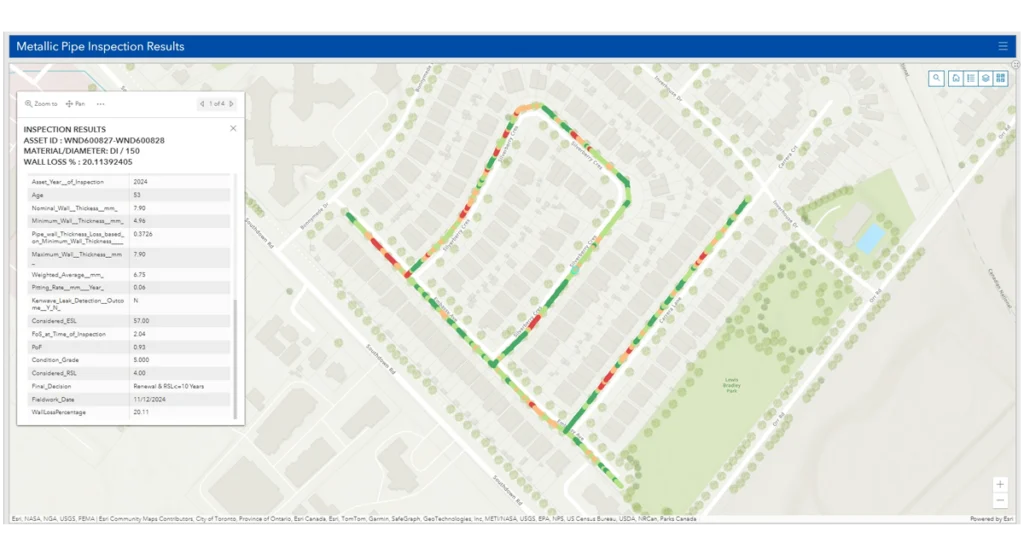

- DRI™ results were integrated into a GIS-based platform, supporting enhanced data management, spatial analysis, and trend identification to inform decision-making.

The Outcome & Value

By combining advanced inspection data with risk-based analytics, the Region has established a data-driven framework that maximizes the impact of every capital dollar spent. The integration of field results into its DSS enables more accurate prediction of wall-loss progression and service life, reducing uncertainty in long-term planning.

This approach allowed Peel to confidently target high-risk metallic mains for renewal while deferring investment in assets that remain in acceptable condition. The result is an optimized capital plan that reduces the likelihood of premature failures or unnecessary replacements, minimizes service disruptions, and strengthens the long-term resilience of the water system.

Data Representation

KenWave delivered a GIS-based asset condition geodatabase that transforms detailed inspection results and analysis into practical decision support for water infrastructure planning and management. The geodatabase stores pipe wall thickness measurements averaged over approximately 2 metres, pitting rate results, and associated predictive outputs. It also includes asset-level attributes such as probability of failure, remaining service life, and condition grading.

Integrated within the Region’s GIS environment, the geodatabase enables consistent risk assessment across the network, supports trend identification, and helps prioritize rehabilitation and renewal activities through intuitive visualization. This deliverable strengthens the Region’s data management capabilities, reinforces its risk-based decision-making framework, and supports long-term lifecycle management of critical water assets.

Key Takeaway

The Region of Peel’s proactive adoption of vibroacoustic inspection to enhance its existing risk-based modelling represents a new benchmark for data-driven asset management. By leveraging Dynamic Response Imaging™ as a foundation for improving predictive modelling, alongside advanced decision support tools, the Region has demonstrated how:

- Non-invasive vibroacoustic technology can deliver actionable condition data for iron metallic mains.

- Watermain inspection and renewal candidates can be prioritized more effectively through a data-driven approach rather than relying solely on their age.

- Integrating field inspection results into risk models helps refine deterioration curves and predict service life.

- Data-driven planning optimizes capital allocation, reduces uncertainty, and strengthens long-term system reliability.

The Region’s integrated approach shows how turning vibroacoustic response data into actionable insights can transform renewal priorities—delivering safer, smarter, and more sustainable infrastructure management.