The Hidden Giant: Why Asbestos Cement Pipe Still Matters in 2025

The Forgotten Risk in Water Infrastructure

Beneath our cities lies a material many assumed had been phased out decades ago: asbestos cement (AC) pipe. Once marketed as lightweight, strong, and corrosion-resistant, AC mains were installed extensively from the 1930s through the 1970s. They promised to deliver clean water to rapidly growing urban populations at lower cost than traditional materials.

Fast forward to 2025, and AC is still with us—embedded in water networks across North America and around the world. In the United States alone, more than 630,000 miles of AC mains remain active. In Canada, the proportion is similar, with about 18 percent of all drinking water pipes made from AC. Most of this infrastructure is now 40 to 70 years old—well past its intended design life—and utilities face mounting consequences as it begins to fail.

What makes AC a “hidden giant” is not only its sheer scale but the fact that it has been largely overlooked in the broader infrastructure conversation. Roads, bridges, and even lead service lines dominate headlines, while AC quietly carries drinking water to millions. The risks are real: catastrophic breaks, costly emergency repairs, and concerns over asbestos fiber release during uncontrolled failures.

The Scale of the AC Pipe Challenge

The numbers alone are staggering. In the U.S., AC makes up nearly one-fifth of all distribution mains. Many cities rely on it for large portions of their networks. San Diego still operates roughly 2,000 miles of AC mains, which contributed to more than 300 breaks in just a three-year period earlier this decade. East Bay Municipal Utility District (EBMUD) in Oakland manages about 1,260 miles—30 percent of its total system—and has accelerated its replacement program to 20 miles per year just to keep pace with failures.

In Canada, the challenge is equally severe. Regina’s system is 67 percent AC, translating into nearly 600 kilometers of brittle, failure-prone pipe. Winnipeg has more than 700 kilometers, representing a quarter of its water mains. In British Columbia, communities such as Prince George and Terrace report that one-third to two-thirds of their networks are AC. Breaks in these regions often trigger boil-water advisories, traffic disruptions, and costly emergency responses.

Globally, AC pipe remains entrenched as well. The United Kingdom operates roughly 31,000 miles, most of it more than 50 years old. Australia manages about 40,000 kilometers of AC water and sewer mains, many approaching end-of-life. And in parts of Eastern Europe and Asia, AC was installed even later, meaning large inventories are only now entering their critical aging phase. The message is consistent worldwide: AC is not a relic of history—it is an active, aging risk in modern water systems.

Why AC Pipe Has Been So Difficult to Inspect?

One of the greatest challenges with AC mains is the lack of safe, practical inspection methods. Traditional approaches have relied on coupon sampling—cutting out small sections of pipe wall for laboratory testing. This is invasive, exposes workers to asbestos fibers, and provides information only about the isolated spot where the coupon was taken.

As a result, most utilities have had to rely on indirect indicators such as break history. Yet this is a poor predictor of future performance. AC pipes can deteriorate unevenly; one segment may remain sound while an adjacent section is already compromised. Without direct data, utilities are left to either replace long stretches of pipe unnecessarily or risk failures by doing too little.

This inspection gap has fueled a cycle of guesswork: capital programs that overspend on good pipe, followed by emergency responses when unseen weak spots collapse. Both outcomes drain budgets and erode public trust.

A New Approach: KenWave’s Dynamic Response Imaging™

KenWave developed Dynamic Response Imaging™ (DRI™) to break this cycle. DRI is a non-invasive solution designed specifically to evaluate the condition of buried mains, including asbestos cement.

Instead of cutting into the pipe, DRI uses carefully tuned vibroacoustic signals introduced through existing access points. Sensors capture the resulting vibration patterns, which are analyzed by advanced algorithms to determine wall stiffness and estimate remaining structural capacity. The process is quick, does not interrupt service, and avoids any disturbance of asbestos fibers.

For utilities, the advantages are transformative:

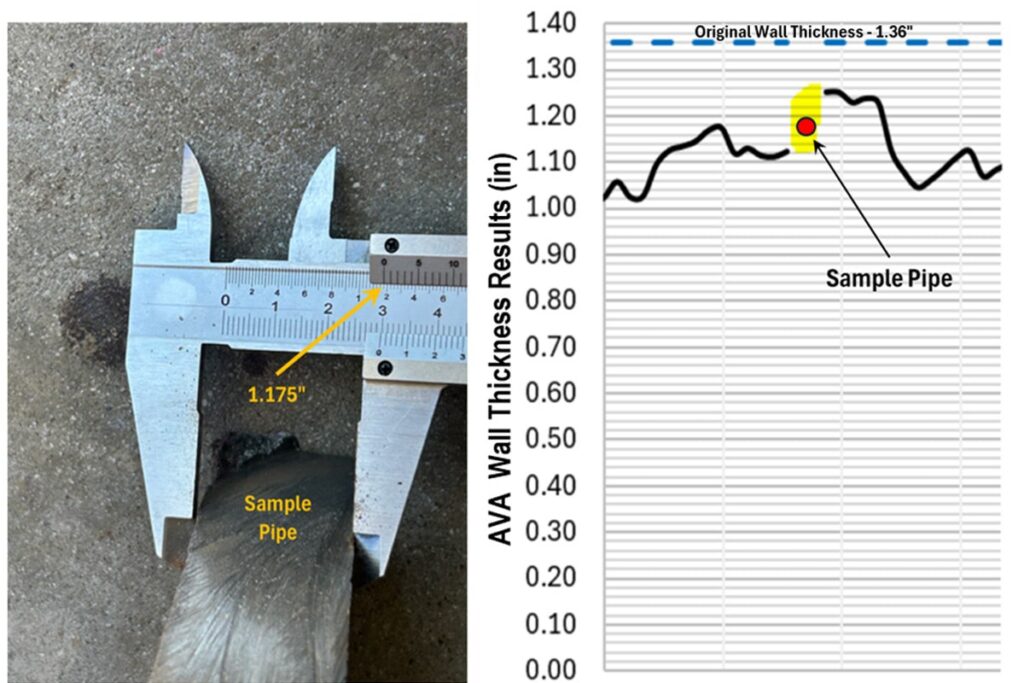

- Accuracy: Independent trials have confirmed engineering-grade precision, typically within ±6 to ±10 percent of actual wall thickness.

- Scale: DRI inspects long, continuous pipe runs, not just isolated coupons.

- Safety: No cutting, no direct handling of asbestos, no shutdown of service.

- Actionable output: Results are delivered as geospatial condition maps, pinpointing which segments are strong and which are at risk.

In effect, DRI turns AC pipe from an unknowable liability into a manageable asset.

Proof in Practice: Brabant Water Case Study

The breakthrough came in the Netherlands, where Brabant Water faced the same challenges as many North American utilities: thousands of kilometers of aging AC mains with no safe way to evaluate them. Partnering through Isle Utilities’ Trial Reservoir, Brabant tested KenWave’s DRI solution on sections of its network.

The results were compelling. DRI achieved ±6 percent accuracy across 83 percent of the inspected length and ±10 percent across 98 percent. For the first time, the utility could see a detailed picture of AC pipe condition without destructive testing. That insight allowed Brabant to target replacements, defer renewals where the pipe was still sound, and avoid unnecessary asbestos exposure.

This validation project demonstrated that AC pipe can be inspected at scale, safely and reliably. It also proved that DRI integrates seamlessly with existing asset management frameworks, giving utilities data they can immediately use to prioritize capital spending.

What This Means for North American Utilities

For utilities across the U.S. and Canada, the implications are clear. AC pipe is everywhere—2,000 miles in San Diego, 67 percent of Regina’s system, one-third of networks in many BC communities. With break rates rising and budgets stretched thin, doing nothing is no longer an option.

KenWave’s DRI offers a third path between wholesale replacement and blind risk: inspection-first planning. By mapping actual condition, utilities can focus renewal dollars where they matter most, avoid asbestos disturbance, and extend the service life of good pipe.

As regulatory pressures mount and climate events strain systems, inspection-first approaches will be critical to sustaining reliable water service. Utilities that act now will be better positioned to manage risk, secure funding, and deliver long-term resilience.

From Hidden Giant to Managed Asset

Asbestos cement pipes remain one of the most widespread and underestimated risks in modern water infrastructure. With more than 630,000 miles still active in the U.S. and nearly one-fifth of Canadian networks, the scale alone demands urgent attention. The financial and public health risks of ignoring AC pipe are too high.

KenWave’s Dynamic Response Imaging™ provides a proven, non-invasive solution that transforms uncertainty into clarity. By turning data into action, utilities can replace only what needs replacing, safeguard workers and communities, and ensure their networks are ready for the future.

Why Utilities Are Turning to Dynamic Response Imaging™?

✅ Non-invasive, external platform

🔧 Works through valves, hydrants, and access points

- 🛰️ Detects wall thinning, pipe class changes, leaks

- 📏 5–20 ft sub-pipe stick resolution

🧠 Ideal for sub-transmission and hard-to-inspect pipes

📊 Supports capital planning with real-world data

Partnered with Leading Utilities & Consultants Globally